Steering the Ship: The PICO-TWL4

Given the delicate balance of functionality and environmental stability required, AAEON’s PICO-TWL4 stood out as the perfect platform to help the customer on their journey.

Quad-Core Processing with Low-Power States

The PICO-TWL4 is available in models powered by either the Intel® Core™ 3 Processor N355 or Intel® Processor N150, both part of the efficiency-focused Intel® Processor N-series (formerly Twin Lake). For their project, the customer opted for the model featuring the Intel® Processor N150, as it offered both the processing power required for the AUV to function reliably while also maintaining a low power footprint.

Despite the Intel® Processor N150 operating at a base power of only 6W, its four cores and relatively high clock frequency made it more than sufficient when it came to executing parallel tasks like sensor fusion from peripherals, payload control, and handling navigation data. In addition to this, the PICO-TWL4’s BIOS enables CPU C-states by default and supports S3 mode, allowing the board to dramatically reduce its power draw when the AUV did not require active processing, and seamlessly resume operation when needed.

Environmentally Sound Customization

The PICO-TWL4’s low-power, efficiency-focused processing platform boosted the distances the AUV could travel while also extending the time it could continuously operate, allowing researchers to undertake more ambitious projects. However, AAEON also customized the board, replacing the standard lithium battery with a supercapacitor.

While this customization was initially requested due to the fact that supercapacitors can be charged and discharged almost endlessly without major degradation, which suited the use scenario of the AUV, it also drastically reduced the downtime of the AUV. Charging speeds for supercapacitors hover at around 300 seconds, while lithium batteries often take several hours, representing a major barrier to research expeditions in largely remote places.

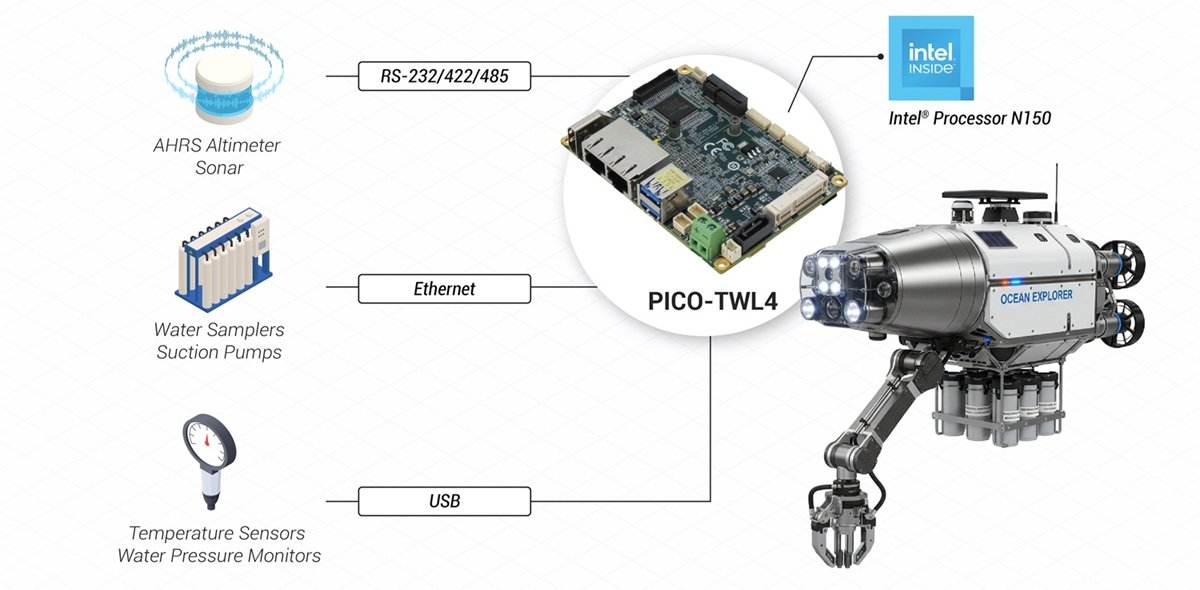

Multi-Sensor Support

While the PICO-TWL4 measures in at only 100mm x 72mm, it provided a variety of interfaces to support the sensors required by the AUV to acquire navigation and positional data. Chief among these features was a 40-pin header that provided four COM port connectors, two offering RS-232/422/485 protocols and two offering RS-232.

To ascertain the AUV’s dead reckoning and altitude in relation to the seabed, two of the COM port connectors supported an Attitude and Heading Reference System (AHRS) and an altimeter, respectively. The former ensured the AUV could be accurately tracked, providing 3D orientation and both absolute and relative heading data in real-time, while the latter enabled the vehicle to avoid collision with nearby obstacles and the seabed itself. A third COM connector from the header was used to install a sonar, facilitating safe movement by identifying objects in the AUV’s path and contributing to local mapping for path planning.

Additional sensors were incorporated into the AUV through the PICO-TWL4’s two USB 3.2 Gen 2 ports and four internal USB 2.0 connectors. These included auxiliary peripherals for more mission-focused data acquisition, such as sensors to monitor temperature, water pressure, and distance.

Real-Time Payload Control

In order to collect samples from the seabed, the AUV’s central computing unit needed to have a method of communicating with motion-control devices. This is where the PICO-TWL4’s dual LAN ports came into play. Boasting two RJ-45 ports running at 1GbE and 2.5GbE speeds, the PICO-TWL4 could issue commands to the AUV’s water samplers and suction pumps.

These commands needed to be incredibly precise, given the critical nature of positioning accuracy. The primary interface used to issue motion commands was the PICO-TWL4’s RJ-45 powered by the Intel® Ethernet Controller I226 driver package. This was because the port’s Time-Sensitive Networking (TSN) capabilities, which include functions such as Precision Time Protocol (IEEE 1588) which executed instructions with precise timing relative to navigation sensors, synchronizing 3D positioning data across all inputs. As a result, the AUV was able to implement coordinated multi-payload operation to obtain samples while accounting for other variables tracked by the system’s AHRS, altimeter, and sonar.