- Resources

- Application Stories

- AI-Enabled Waste Sorting Unit

Overview

Public policy and regulatory campaigns aimed at promoting recycling have contributed to a shift in public perception regarding landfill waste disposal. This has been amplified by media, academic research, and private initiatives, increasing society’s emphasis on recycling.

As the volume of materials being recycled has increased, however, the issue has arisen of exactly how material recovery facilities can manage the increasing demands placed upon them most effectively, efficiently, and safely. To meet these demands, one company embraced technological innovation through the development of an AI-enabled waste sorting unit, recruiting AAEON to help them achieve their goal.

The Drawbacks of Waste Material Management

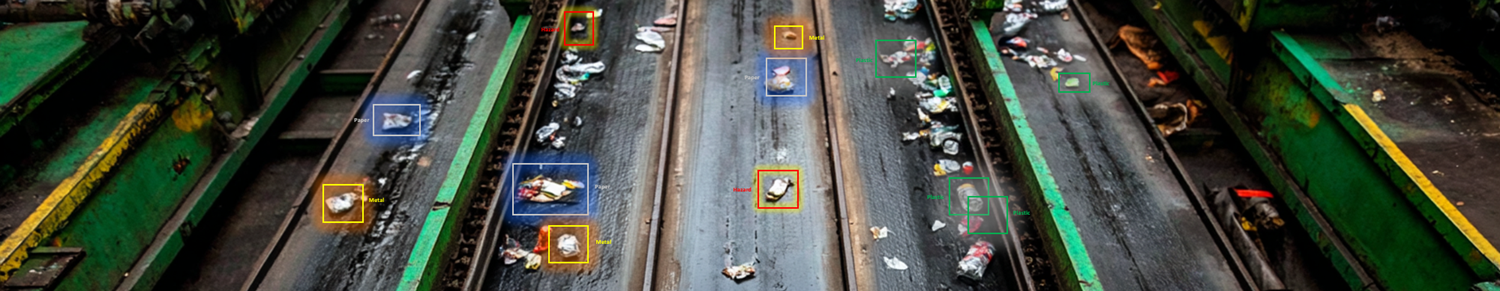

Material recovery facilities fulfil a number of roles in the recycling ecosystem, but a critical function is the inspection of raw recyclable waste for contamination, such as the presence of non-recyclable and hazardous materials within recyclable streams.

The presence of such contamination downgrades the value of the overall material stream, but also poses risks to recovery facility operators and can damage sorting equipment. The most potent example outlining this challenge is other unsuitable waste items in recycling streams, such as electronic materials. Improperly disposed of items not only have the potential to reduce the purity of recyclable outputs for remanufacturing, but significantly decrease overall operational and economic efficiency due to the need for manual sorting of entire batches.

While these issues are important on a macro level, the most substantial risk posed by the presence of hazardous materials within recycling streams is to facility operators, who risk harmful chemical exposure from said materials, while fires caused by incorrectly disposed electronic components are also a major threat.

Project Goals & Requirements

Because of the drawbacks of current waste material management processes, AAEON’s customer wanted to integrate an accurate, automated method for screening recycling streams for hazardous materials and sorting the items within each batch into their corresponding groups to streamline separation into recyclable outputs that could be shipped for remanufacturing.

To achieve this, they knew they required an elite embedded computing solution with precise characteristics.

Latency-Free, On-site Data Processing

Given the sheer volume of material requiring analysis, the solution chosen would need to be able to operate in real-time, processing vast quantities of data concurrently. This was crucial, as it would help categorize recyclable materials and flag hazardous items, protecting both operators and machinery.

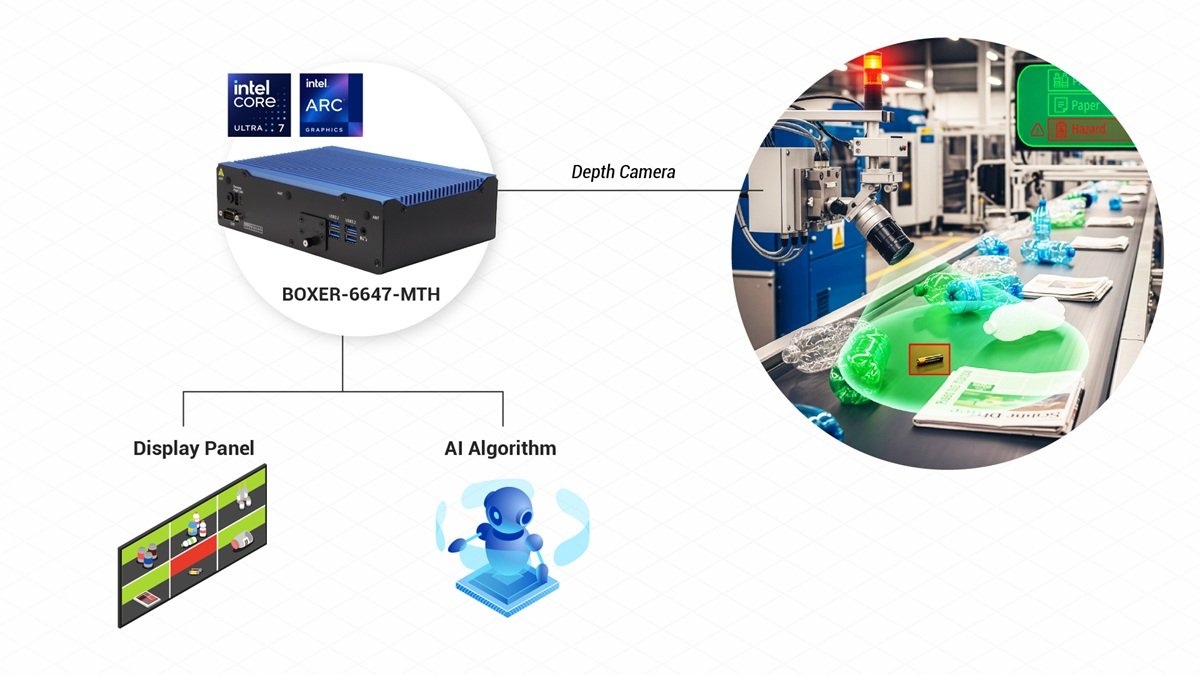

Reliable Peripheral Support

The chosen solution would require camera connectivity to acquire high-quality visual data for analysis. Moreover, it would need to output the AI-enabled waste sorting unit’s analysis to connected display panels for operators to monitor the prevalence of different waste types, as well as relay machine control task instructions based on the data analyzed.

Operational Stability

Finally, the hardware chosen for the task would need to operate reliably in harsh conditions. Similar to manufacturing settings, material recovery facilities pose environmental risks to the operability of embedded PCs, including dust and debris ingress, fluctuating power supplies, and high levels of vibration. Therefore, the solution needed to be robust enough to handle continuous operation in such settings.

The Solution? AAEON’s BOXER-6647-MTH

Integrated CPU, NPU, & GPU

The BOXER-6647-MTH was an exceptionally effective platform to deploy the customer’s pre-trained AI model. This was because its Intel® Core™ Ultra 7 Processor 155H enabling data pre-processing, compute tasks, and parallel AI workload execution, all in one chip.

This platform was capable of multiple functions, both independent and interdependent, meaning the BOXER-6647-MTH could efficiently allocate resources according to the application’s needs. The first example of this is the CPU itself, which had the primary role of pre-processing image data received from the PC’s peripheral camera. However, the CPU’s performance-hybrid architecture meant that it was also able to handle all necessary compute tasks for the AI-enabled waste sorting unit.

With the majority of the application’s compute tasks handled by its CPU, and less intensive AI tasks offloaded to its integrated NPU, the BOXER-6647-MTH’s integrated Intel® Arc™ GPU was able to focus on high-throughput parallel processing. This meant that resource-heavy tasks such as object classification and image segmentation could be undertaken by the system’s GPU while maintaining high frame rates, reducing latency.

As noted, the BOXER-6647-MTH relied on the Intel® Core™ Ultra 7 Processor 155H‘s Intel® AI Boost NPU for low-power AI tasks, such as post-processing analyzed data through confidence filtering and bounding box smoothing, while also performing limited inference tasks offloaded from the system’s GPU. The benefits of this dynamic resource allocation were profound, where the platform’s efficiency not only reduced latency but reduced overall power expenditure, keeping with the customer’s focus on environmental sustainability.

Simple, Robust Interface Selection

The customer’s AI-enabled waste sorting unit’s peripheral connectivity needs were relatively straightforward, with quality being favored over quantity. However, it did need to support a camera with sufficiently advanced speed for high-quality image acquisition.

The BOXER-6647-MTH offered a number of suitable options for this, including four USB 3.2 Type-A and three RJ-45 ports, two supporting 2.5GbE and the other 1GbE. In this instance, the customer used the system’s USB options to install an Intel® RealSense™ Depth Camera D456, which provided high-resolution depth and RGB data to the BOXER-6647-MTH without requiring additional hardware or custom drivers.

Offering 10Gbps bandwidth, the BOXER-6647-MTH’s USB ports made it possible to transmit large volumes of image data from the connected camera without compression delays, maintaining low latency. An additional benefit to this was the plug-and-play nature of the camera’s design, which simplified deployment.

The BOXER-6647-MTH’s two HDMI ports also provided connectivity to the company’s display panels, giving operators a sophisticated, clear dashboard on which to monitor the application’s analyzed data. This cloud-level insight into the application’s operations also allowed for device-level instructions to be implemented through the BOXER-6647-MTH’s serial interfaces.

The BOXER-6647-MTH also offered two DB-9 ports for RS-232/422/485 signals, allowing for the integration of weight sensors and motor controllers to allow for real-time volume data collection and synchronization between conveyor belt speed and AI output, respectively.

Environmentally Robust

As with any industrial application, the AI-enabled waste sorting unit would be deployed in challenging operating conditions, which was another reason the customer chose the BOXER-6647-MTH.

Compact at just 220mm x 154mm x 62.1mm, the BOXER-6647-MTH was well-suited to installation with the customer’s existing waste sorting units, while also providing flexibility in deployment across different premises as a result of its broad 9V to 36V power input range. The major benefit to this range was that it ensured the device could remain operational even during unstable power conditions, reducing downtime.

The BOXER-6647-MTH was also an exceptionally durable option for fluctuating facility temperatures, with a -20°C to 60°C temperature tolerance allowing optimal performance to be maintained, even in extreme conditions. Moreover, the advanced anti-vibration and anti-shock features of the device made it a reliable choice for the intended environment.

Application Architecture

Impact & Future Outlook

Following the integration of the BOXER-6647-MTH, the customer was delighted with the impact that leveraging AI had on its waste sorting unit, noting the speed, accuracy, and consistency with which it could optimize the sorting process. With contaminated, incorrect, or hazardous material automatically categorized and removed from recycling streams prior to processing and batching, the customer effectively eliminated one of the biggest problems faced in the recycling industry today.

Though the initial project concluded successfully, it also marked a new beginning. With further plans already in place to expand the rollout of their AI-assisted waste sorting unit, the customer has shown that the challenges their industry faces are not insurmountable, and can be presented as an example of the potential of AI and edge computing in helping institutions reach sustainability goals.