- Resources

- Application Stories

- COM-RAPC6 Humanoid Robotics Project

With a substantial history of providing innovative platforms with which to develop advanced robotics applications, system integrators often approach AAEON with project concepts aimed at eliminating specific pain points that exist in vertical market applications. Examples of such pain points include the bottlenecks that occur in manufacturing quality assurance due to human error or environmental constraints for embedded systems deployed in harsh settings.

For one of AAEON’s recent customers, however, an award-winning organization with the objective of developing humanoid robots for both advanced university robotics programs and commercial enterprises, the primary motivation was not to address a specific industry pain point, but to realize the technological capabilities of autonomous humanoid robotics for needs that may not yet even have arisen.

This focus on technological advancement over specific commercial needs provided AAEON with opportunities and challenges in equal measure, meaning that rather than working with the customer to bring a solution to market, the aim was to assist the customer in achieving their vision of building the most advanced, versatile humanoid robot possible.

Bridging Precise Real-Time Control with Advanced AI Inferencing

The key factors that distinguish the type of advanced autonomous humanoid robot AAEON’s customer sought to develop, and standard rules-based industrial robots such as robotic arms deployed in factories are the presence of both real-time mechanical control and autonomous decision-making based on advanced AI algorithms.

Pairing these two aspects is something AAEON is well-versed in, given its broad catalog of AI platforms equipped with world-class integrated GPU architectures and development tools. However, the customer’s objective was not to create a robot to execute specific tasks, but to give the global development community a future-proof, modular hardware framework that could be adapted and upgraded to utilize future advancements with respect to both hardware and software.

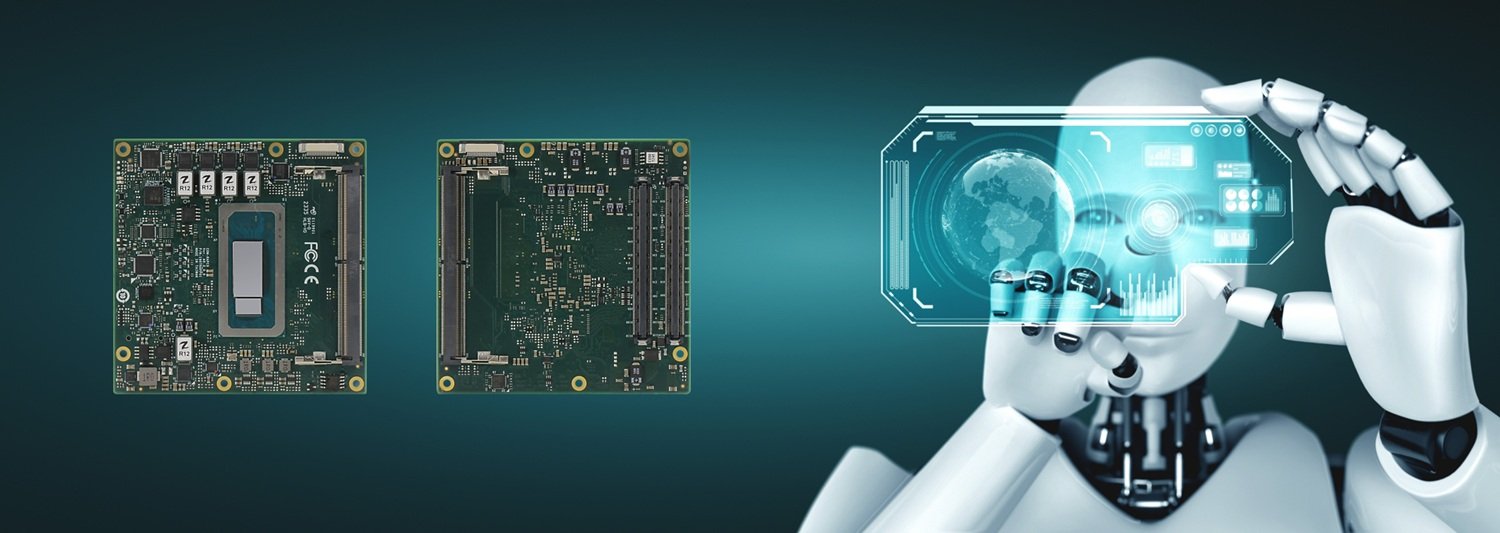

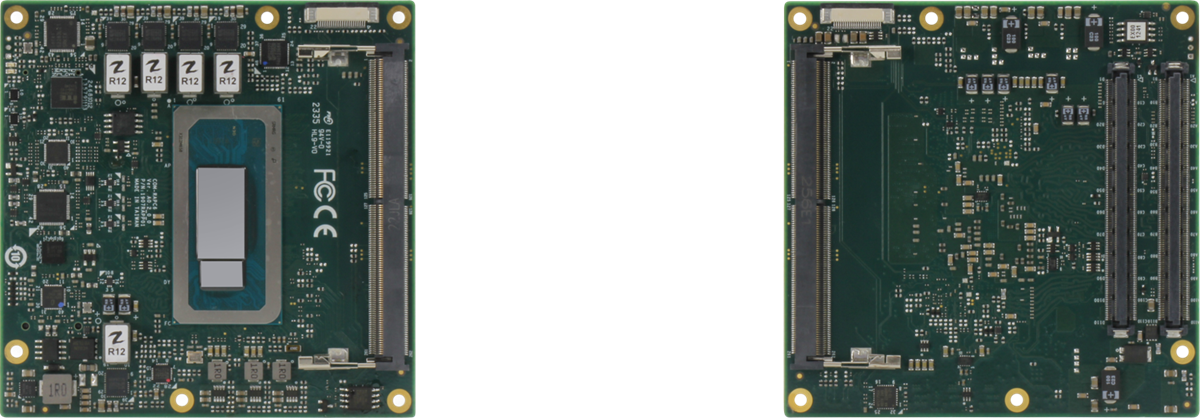

Identifying a comprehensive embedded platform capable of high-level operation while still being future-proof was a major challenge faced by the customer, and so they opted for a modular build that separated the components responsible for mechanical control and AI inference. For the former, the clear winner in terms of suitability came from AAEON’s range of Computer-on-Modules (COMs), with the customer ultimately opting for the COM-RAPC6, a COM Express Type 6 module powered by 13th Generation Intel® Core™ processors. Meanwhile, the customer chose to incorporate an NVIDIA® Jetson AGX Orin™ module to handle heavy-duty AI inferencing tasks.

Agile Architecture as the Key to Success

With the COM-RAPC6, the customer had a platform equipped with an array of connectors conducive to establishing real-time communication between sensors, actuators, and mechanical control systems, including I2C, SMBus, and an 8-bit GPIO. The robot was equipped with a custom carrier board, which AAEON’s Q-service carrier board design support team subjected to extensive compatibility testing, to serve as a conduit between the COM-RAPC6 and the robot’s NVIDIA® Jetson AGX Orin™ module, maintaining real-time synchronization between the two. As a result, the COM-RAPC6 could provide the NVIDIA® Jetson AGX Orin™ module with real-time status updates from actuators and sensors to give it awareness of the robot’s posture, force application, and balance. Conversely, this bilateral communication provided a route for the NVIDIA® Jetson AGX Orin™ module to communicate its algorithm-derived decisions, which could be used by the COM-RAPC6’s GPIO to execute pre-programmed action sequences.

By offloading the mechanical control task management of the application from the robot’s NVIDIA® Jetson AGX Orin™ module, the COM-RAPC6 reduced compute bottlenecks and allowed the module to instead maximize inferencing performance, leading to faster, more accurate decision-making.

Given the performance-hybrid architecture of its 13th Generation Intel® Core™ CPU, the COM-RAPC6 provided the robot with a substantial processor base capable of handling multiple sensor streams simultaneously without risking system overload. Despite the control and AI functions of the robot being handled by separate components, high-energy tasks or voltage fluctuations could still lead to system instability.

AAEON – particularly when it comes to its Computer-on-Modules line – prides itself on its customization capabilities. As such, the customer was provided with a tailor-made BIOS with firmware-level optimizations that ensured the COM-RAPC6 prioritized critical real-time tasks over background processes, as well as modifying the parameters of the module’s CPU power states and sleep modes to account for variable power loads.

The Project Impact of AAEON’s COM-RAPC6

Ordinarily, emphasis is placed on one crucial ingredient of an application’s architecture that can be framed as the primary driver of its success. In this case however, the primary benefit the COM-RAPC6 brought to the customer was its excellent execution of supporting functions.

By the very nature of Computer-on-Modules being PICMG standardized, they offer an incredibly easy route to upgrade as generational feature improvements or project interface changes arise. As such, the integration of the COM-RAPC6 provided the customer with the application’s compute foundation, while allowing for flexibility regarding the interfaces utilized by its connected carrier board.

The vendor agnosticism of the platform adds to this, meaning that unlike a fully integrated system-level solution, the GPU, peripheral cameras, sensors, and other key components of the application can be changed or upgraded without concern about compatibility issues and their ability to work with the module handling the robot’s mechanical control tasks.

As for the impact that AAEON had on the project outside of its product offering, a great deal of customization support was needed in order to make the application viable. This is an area in which AAEON’s Computer-on-Modules division in particular leads the industry, with unmatched service quality and expertise in working alongside its customers to align the specifications of the module deployed to the needs of the customer’s application. In this instance, the customer required substantial firmware customization to fine-tune the COM-RAPC6’s BIOS to suit the power requirements of the robot, as well as general carrier board design and testing services — both of which were instrumental to the success of the project.

The Project’s Role in Advancing the Commercial Potential of Humanoid Robots

By successfully developing an autonomous humanoid robot with such high standards of both performance and modularity, the project can be seen as both a deployment-ready solution easily configured to address pain points within various industries and a robust blueprint for the next generation to expand upon.

With the client’s key customer bases being both enterprises seeking to adopt AI into new and exciting commercial arenas and the broader development community, AAEON sees this as the first step towards the next generation of advanced robotics. Given the future-proof foundation and modular approach to the robot’s engineering, it is easy to see it used as the foundation for greater commercialization in the field in coming years.